ResolveEI engineers primarily design mechanisms, parts and enclosures for the

products we help our customers develop. This involves the creation of 3D part

datasets for machined parts, assessing them for manufacturability, and determining

their manufacturing sequences and processes. It may also involve the creation of

3D moving models of multiple parts, determining interferences, checking range of

motion as well as providing individual and assembly part drawings and datasets.

They have a broad and complete set of tools with which to carry out mechanical design,

fabrication, and assembly. It of course begins with a selection of fully integrated CAD

programs and stations to generate the 3d datasets for parts and assemblies. After generation,

the parts can be immediately 3D printed in ABS plastic for form, fit, and function checks.

Various in-house mold options can be considered from silicon to a soft metal foundry for

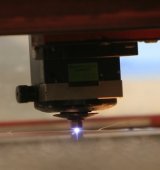

metal casts if needed. A fully automated machine shop can also be considered for CNC machining

lathe and laser cutting. Your product benefits, as most, if not all, aspects of its design

and generation, from the mechanical and electrical, all the way through to its software and testing,

is done in a one-stop, in-house product development company.

After you're satisfied with the function and performance of your product, and quick turn around is no longer a factor, we help you transition all of your product's design datasets to reputable suppliers and fabricators. Again, the datasets are your property, purchased with your contract. If you desire, we'll help you oversee its pre and full production cycles with a proven manufacturing partner and get you on your way. Your marketable product is our primary concern.